Skip to content

CloudFactory Manufacturing Execution Systems based upon Microsoft Dynamics 365 Business Central Manufacturing Edition reduces rework and returns by enabling you to track information that pertains to quality. Whether you need to collect information for audits, comply with 3rd party regulations, track batch information, check that shipments are prepared correctly or ensure parts are produced within specification,

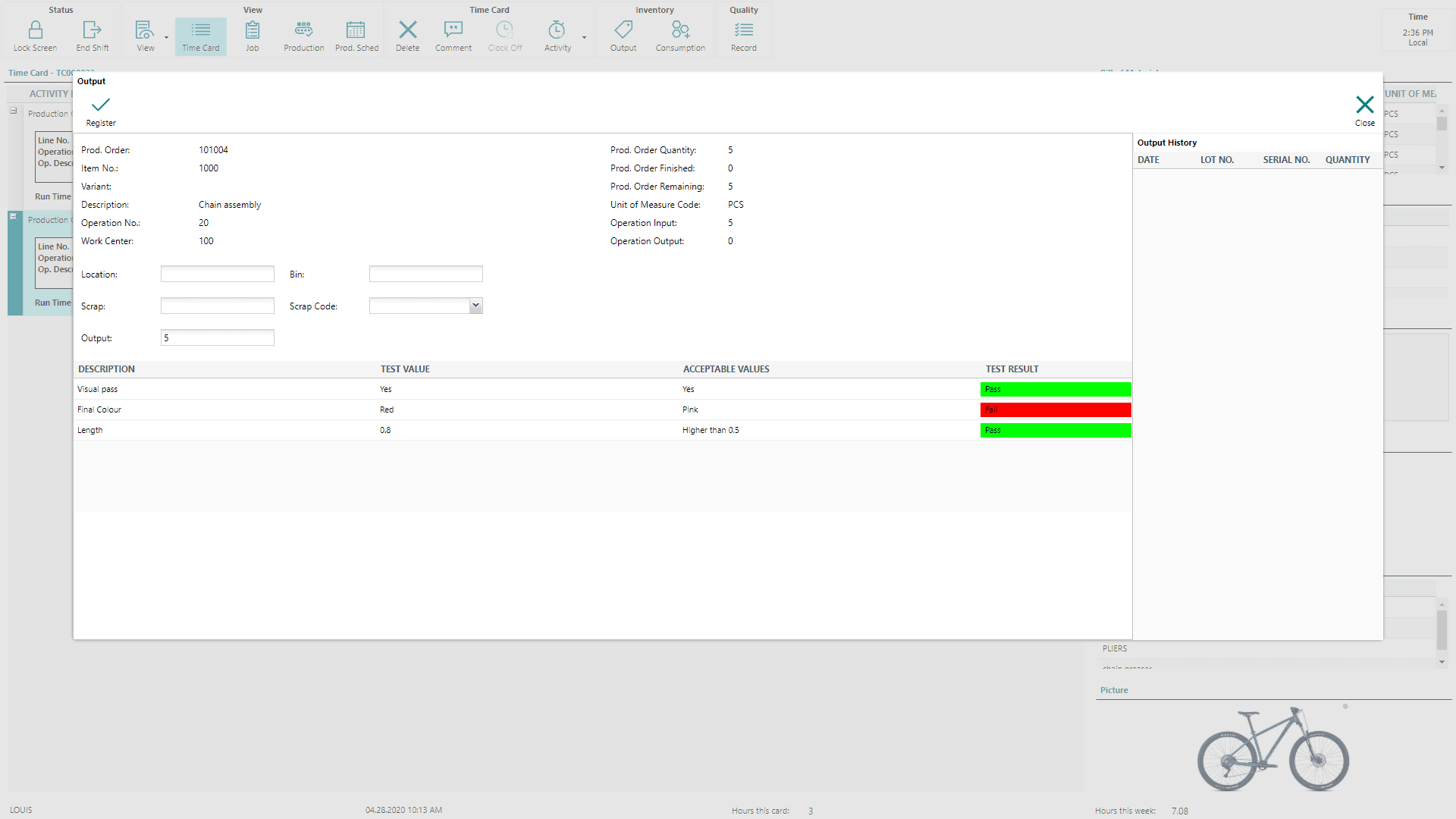

When it comes to monitoring quality, the task can be assigned to an employee, asset or process. In addition to the quality information you choose to collect, pass/fail parameters can be configured to confirm acceptance or indicate a problem that needs to be resolved.

"Quality Control in Manufacturing" may be defined as a process that ensures customers receive products devoid of defects and that also meet their needs. The problem is, when approached incorrectly, this process can put consumers at risk.

But how?

Lets consider the defect discovered in Takata airbags, which resulted in the largest automotive recall in history – a recall that included almost 69 million airbag inflators and threatened to cost billions of dollars. This recall started in 2018 and still in recent time, December 2021, Toyota was recalling cars as part of the global recall. But major recalls like these can looked to be prevented through effective quality control in manufacturing.

Some common tools used to support quality control in the manufacturing sector include:

Because we raise “tracking,” let’s now introduce “Tracking Quality” within the manufacturing process for Microsoft Dynamics 365 Business Central Manufacturing.

CloudFactory are delighted to enable a solution for Quality Tracking table Microsoft Dynamics 365 Business Central Manufacturing as part of an overall Manufacturing Solution which is a comprehensive approach to:

Amidst the myriad of incredible features Shop Floor Insight offers is its quality tracking module, and this is one such way productivity tools are helping manufacturers manage the quality assurance process.

The Quality Tracking Module enables manufacturing personnel to easily manage their quality assurance process for the purpose of increasing customer satisfaction, Shop Floor Insight’s quality tracking module helps reduce redundant work and returns by allowing staff to track information that relates to quality – whether it be to collect information for audits, comply with third-party regulations, track batch data, check that shipments are prepared correctly or ensure parts are produced within spec.

“The bottom line is that with a solution like this, our clients are in control” Said Wendy Jansz - Practice Director – Cloud Solutions

We totally understand that in the manufacturing world, customers expect and demand high-quality products. When bringing quality tracking processes into the mix, you can rest assured knowing your operations will ultimately:

Summary

It’s a known aspect that manufacturers who put in place quality control and tracking processes are far less likely to experience recalls on their products, or place customers at risk from poorly-made items. And, don’t forget: The costs associated with these recalls can indeed be steep and think about the Takata airbag recall we mentioned....!

Why not join us for your personal review - click below to Learn More and Register