Microsoft Dynamics 365 Business Central Manufacturing Management

By deploying the features of Microsoft Dynamics 365 Business Central Premium Edition our clients unlock robust Manufacturing capabilities across Production, Planning, Forecasting, Version Management, Demand, Finite Loading and Machine Centers. Manufacturing coupled with great capability across Finance, Service and Supply Chain makes Business Central a compelling solution for the Modern Manufacturer!

Assembly to Manufacturing - What is your focus?

.png?width=900&height=439&name=Business%20Central%20Manufacturing%20(3).png)

Microsoft Dynamics 365 Business Central comprises two editions: Essentials and Premium. Within the Essential Edition Business Central provides for Assembly Management where Manufacturing is simply not required.

So what is Assembly? Assembly is defined as an Item that can be sold and will comprise an Assembly Bill of Material (BOM)

What functions are typically supported for an Assembly Focused Business?

-

Assemble to Order and Assemble to Stock Process

-

Quote an Assemble-to-Order Sale

-

Assemble Items

-

Sell Items Assembled to Order

-

Sell Inventory Items in Assemble-to-Order Flows

-

Sell Assemble-to-Order Items and Inventory Items Together

-

Create Blanket Assembly Orders

-

Undo Assembly Posting

-

Bills of Material

.png?width=900&height=439&name=Business%20Central%20Manufacturing%20(3).png)

Microsoft Dynamics 365 Business Central comprises two editions: Essentials and Premium. Within the Premium Edition Business Central provides for Assembly Management and Manufacturing capability.

To convert material into produced end items, production resources, such as bills of material, routing's, machine operators, and machinery must be set up in the system.

Operators and machines are represented in the system as machine centres that may be organised in work centres and work centre groups. When these resources are established, they can be loaded with operations according to the item's defined material (BOM) and process (routing) structure, and according to the capacity of the machine or work centre. You can also set the production capacity of each resource. Capacity is defined by the work time available in the machine and work centres, and is governed by calendars for each level. A work centre calendar specifies the working days or hours, shifts, holidays, and absence that determine the work centre’s gross available capacity (typically measured in minutes). All of this is determined by defined efficiency and capacity values.

When you have set up manufacturing, you can plan and execute production orders. For more information, see Planning and Manufacturing.

What function comprises Microsoft Dynamics 365 Business Central Manufacturing?

-

Production Bill of Materials

-

Production Orders

-

Supply Planning

-

Capacity Planning

-

Version Management

-

Master Production Scheduling

-

Materials Requirements Planning

-

Automatic production orders and purchase orders.

-

Action messages for fast and easy balancing of supply and demand

-

Support for bucket-less and bucketed material requirements planning

-

Demand Forecasting

-

Sales and Inventory Forecasting

-

Finite Loading

-

Machine Centers

Why Microsoft Dynamics 365 Business Central Manufacturing Management?

With Microsoft Dynamics 365 Business Central’s Manufacturing Management modules, simply made available by selecting the Premium Subscription Edition, your manufacturing processes become completely integrated and deliver a coherent approach to your business management.

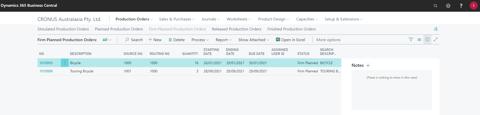

Business Central Production Order

Before proceeding with production, most companies perform supply planning, typically once a week, to calculate how many production orders and purchase orders to execute to fulfill that week’s sales demand. Purchase orders supply the components that are required according to the production BOM to produce the end items.

Production orders are the central components of application's manufacturing functionality and they contain the following information:

- Products planned for manufacturing

- Materials required for the planned production orders

- Products that have just been manufactured

- Materials that have already been selected

- Products that have been manufactured in the past

- Materials that were used in previous manufacturing operations

Production orders are the starting points for:

- Planning future manufacturing

- Controlling current manufacturing

- Tracking of finished manufacturing

Business Central Planning

The planner of a company, such as a purchaser or a production planner is presumed to be the user of the planning system. The planning system assists the user by performing the extensive but rather straightforward calculations of a plan. The user can then concentrate on solving the more difficult problems, such as when things differ from normal.

The planning system is driven by anticipated and actual customer demand, such as forecast and sales orders. Running the planning calculation will result in Business Central suggesting specific actions for the user to take concerning possible supply from vendors, assembly or production departments, or transfers from other warehouses. These suggested actions could be to create new supply orders, such as purchase or production orders. If supply orders already exist, the suggested actions could be to increase or expedite the orders to meet the changes in demand.

Another goal of the planning system is to ensure that inventory does not grow unnecessarily. If demand decreases, the planning system will suggest that the user postpone, decrease in quantity, or cancel existing supply orders.

MRP and MPS, Calculate Net Change Plan, and Calculate Regenerative Plan are all functions within the planning logic and is supported by other routines and processes in Business Central.