Microsoft Dynamics 365 Business Central Manufacturing: Finite Capacity Scheduling

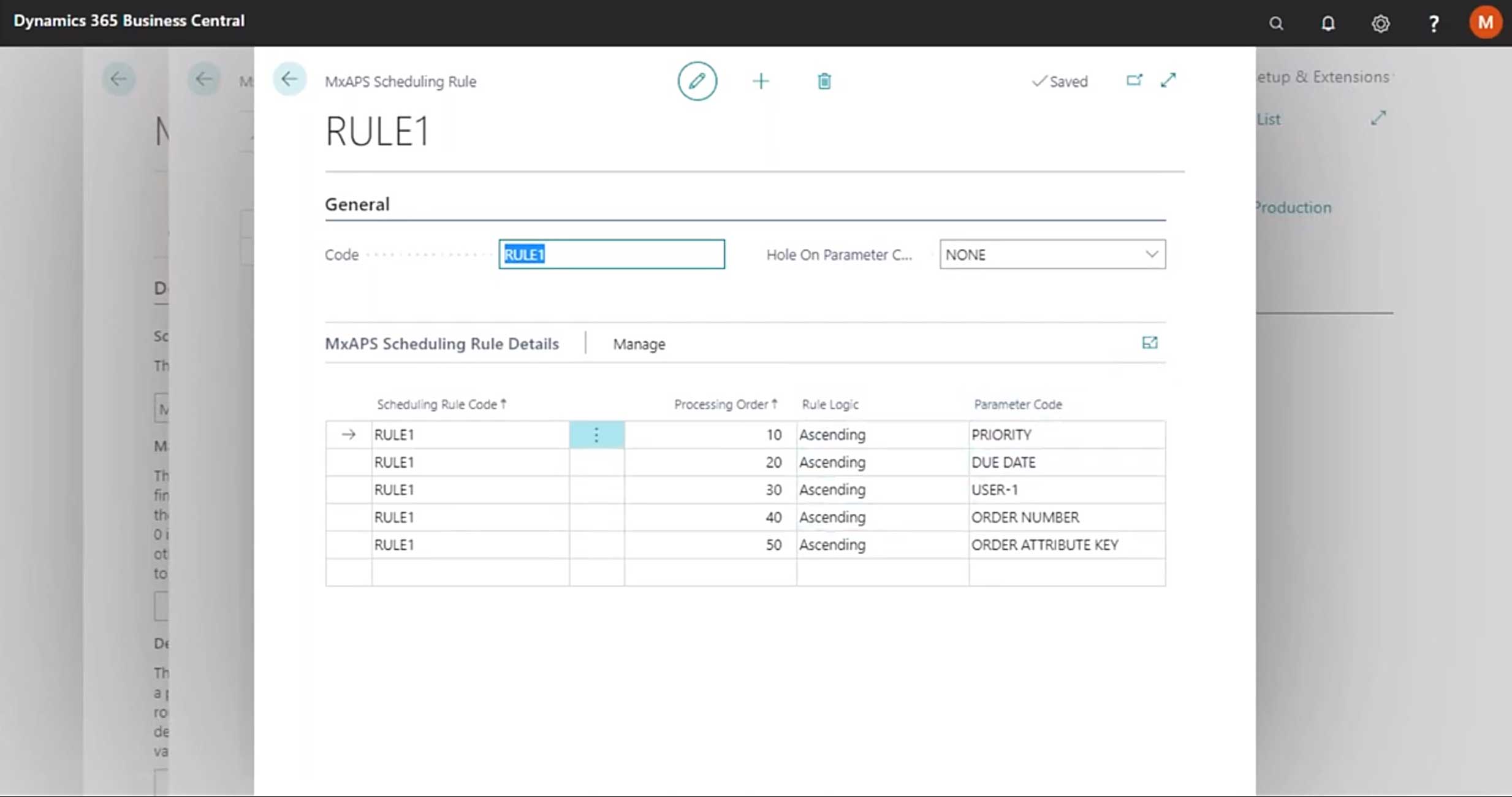

Advanced Finite Scheduling for Microsoft Dynamics 365 Business Central transforms production planning and scheduling from an inaccurate and time-consuming task into a responsive, repeatable, and highly accurate decision support activity.

What Is Advanced Finite Capacity Scheduling for Microsoft Dynamics 365 Business Central?

Advanced Production Scheduling works with your existing Dynamics 365 Business Central Manufacturing system to generate realistic plans for manufacturing your product in the most efficient manner possible. However, the benefits don’t end at the shop floor: efficient production combined with enhanced visibility into the manufacturing process affects almost every other area of your business.

-

Improve customer service levels by producing more realistic production schedules

-

Unlock revenue potential by improving resource and equipment utilization

-

Minimise the cost of production

-

Reduce WIP, finished goods inventory, and lead times

-

Increase throughput, machine utilization and inventory turns

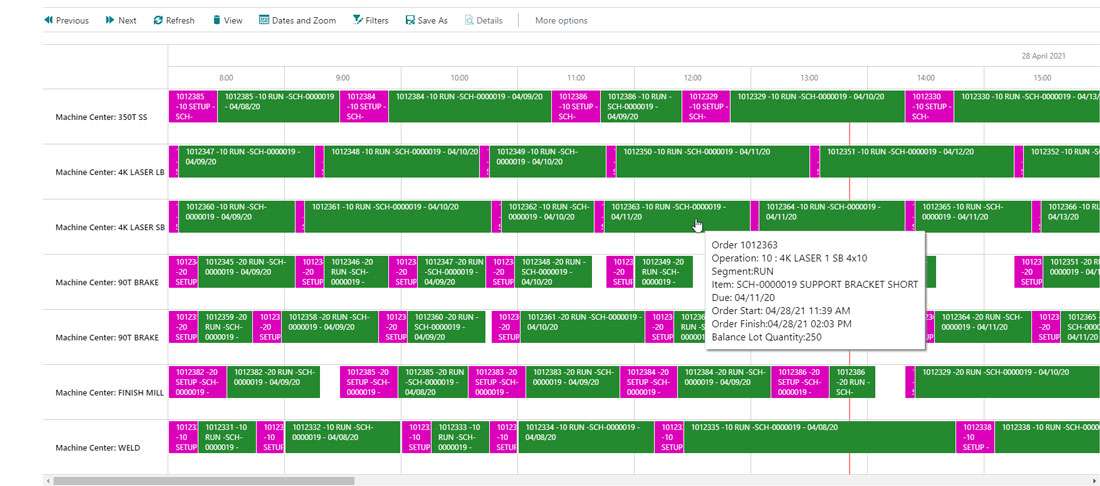

Real-world production planning & scheduling

Traditional methods of planning and scheduling are error-prone, time-consuming, and non-responsive, resulting in schedules that do not accurately reflect the actual capabilities of the shop floor. Your ability to schedule production responsively is further impaired when you factor in production realities, late delivery of critical raw material and components, equipment breakdowns, changes to sales forecasts, and customer demands.

-

Accurate responses to shop floor variations during schedule execution, real-world events and production realities are impossible

-

Static production schedules quickly become invalid

Microsoft Business Central with Finite Scheduling provides for:

-

Quickly generating accurate and efficient production schedules

-

Synchronising customer demand against materials, people, machines and tooling

-

Responding to unplanned events and production realities while maintaining due dates

-

Realising cost containment initiatives while increasing plant throughput

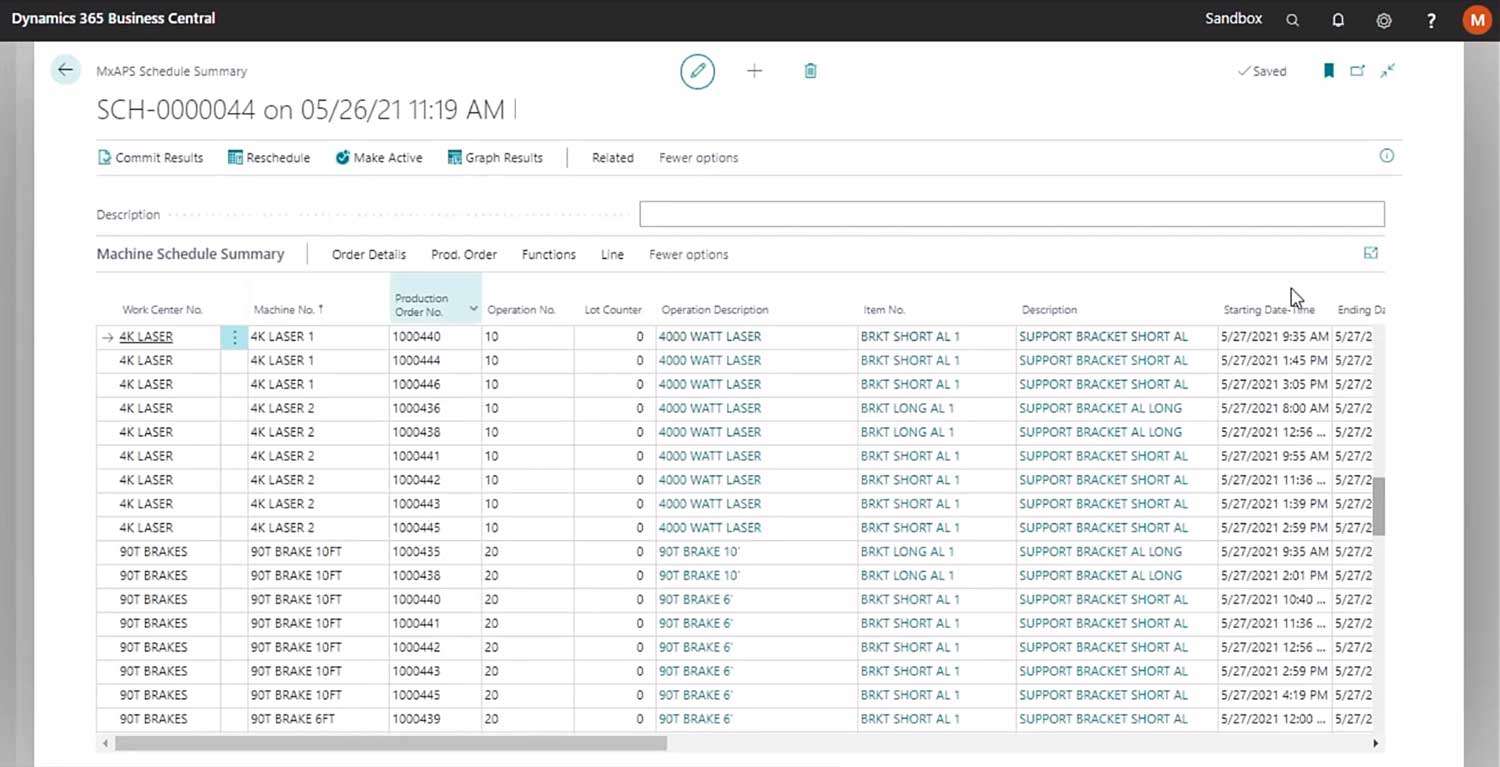

Microsoft Dynamics 365 Business Central Advanced Production Scheduling: Supporting department processes.

Sales

MxAPS allows you to quote realistic delivery dates, and stick to them. If problems should arise during production, sales managers can respond proactively instead of being surprised by unhappy customers.

MxAPS drives earlier delivery dates that ensure happy and loyal customers.

Purchasing

MxAPS can help MRP provide a detailed material requirements plan, allowing you to purchase exactly what is needed, at exactly the right time. Give your purchasing department real-time visibility into priority and quantity of required materials.

Maintenance

Reduce the cost of equipment downtime by using MxAPS to plan maintenance and cleaning when it will be least disruptive to production.

Automatically keep track of actual machine hours between preventative maintenance procedures to ensure equipment stays operational.

MxAPS automatically reallocates production to other areas should a machine go down.

Production

Run a leaner operation to reduce production costs, improve throughput, and better manage all resources and production assets.

MxAPS also helps you improve capacity utilization, reduce downtime, and reduce inventory levels. All these improvements add up to improved production efficiency, which ultimately makes you far more profitable than without MxAPS.

Finance (A/R, A/P, etc.)

Improve your cash flow and reduce inventory costs by reducing raw material, work in progress, and finished goods inventories. MxAPS can help determine the best time to purchase materials and component parts. It also provides realistic data for how many customer orders will ship, allowing you to base your expenditures on realistic revenue expectations.

Shipping and Receiving

MxAPS allows you to reduce freight costs by minimizing the expediting of raw materials and finished product. By knowing exactly when material will be required, and exactly when product will be ready to ship, your shippers can use the most affordable methods available.

Human Resources

Reduce staffing costs with detailed labor plans based on skill sets. MxAPS helps your HR department plan hiring campaigns, temporary worker allocations, and overtime strategies without over-hiring or being caught short-handed.

Scheduled vacations retrieved from HR systems are accounted for in production plans, ensuring that there are no labor shortages or surprises.