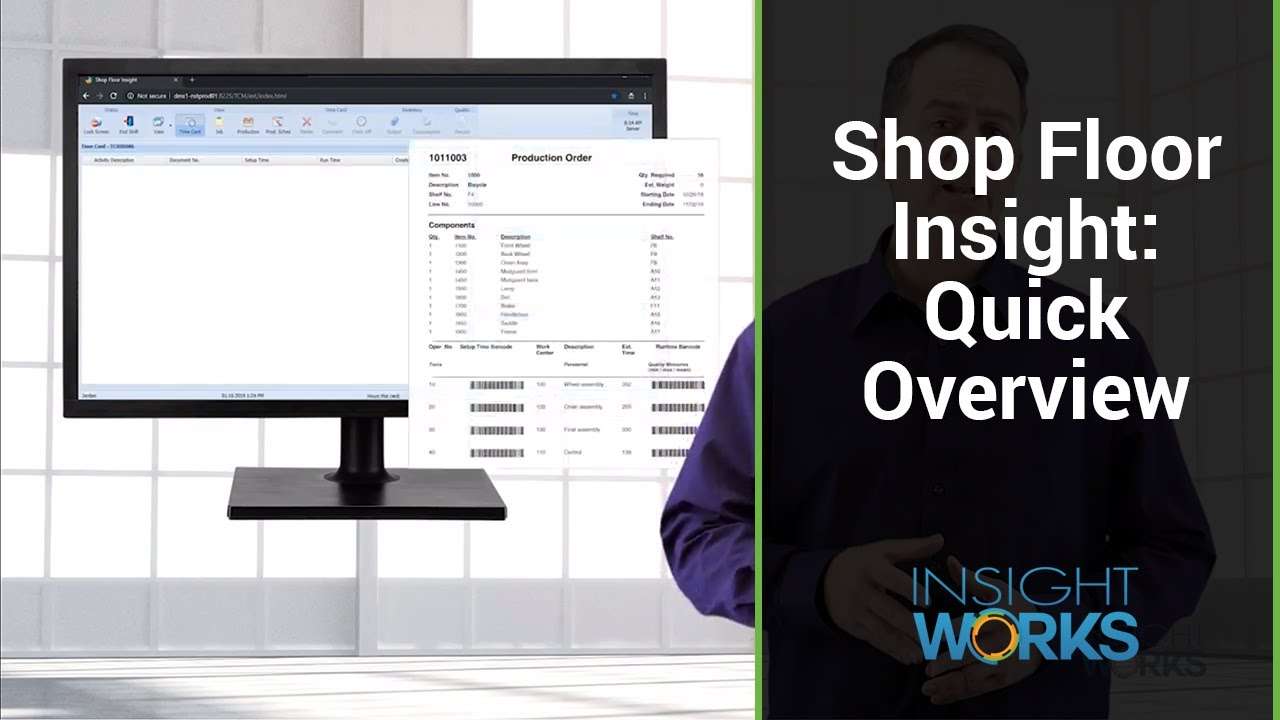

Manufacturing Solutions for Microsoft Dynamics 365 Business Central: Shop Floor Management

A comprehensive Manufactacturing Execution System (MES) for the Shop Floor providing barcoded time capture and employee time management.

What Is Shop Floor Management?

Shop Floor Management refers to the set of practices, processes and systems used to manage and oversee manufacturing operations, particularly at the physical production level within a factory or facility. It involves the coordination, control, and monitoring of various activities that take place on the shop floor to ensure that production processes run efficiently and meet quality and productivity goals. Shop Floor Management includes the following key aspects for Microsoft Dynamics 365 Business Central Manufacturing.

Shop Floor Insights!

-

Time & Attendance

-

Payroll Integration

-

Graphical Dispatch/Scheduler

-

Light Shift Scheduling

-

Barcoded Labour Collection

-

Manual Time Entry

-

Quality Inspections

-

Work Instructions

-

Production Dispatch List

-

Job Despatch List

-

Point-of-Use Consumption

-

Shop Floor Output

-

Analysis Reporting

-

Safety Logbook

Shop Floor Insights is a comprehensive solution for a barcoded Time Capture time and attendance and employee time management.

This capability for Microsoft Dynamics 365 Business Central utilises barcoded production orders to simplify data capture on the shop floor and reduce the errors associated with manual time entry. Using this solution your Shop Floor will capture detailed time data using barcoded scanning for

-

Production orders

-

Jobs

-

Service orders

Maintenance users will obtain operational data on the shop floor or in the field including consumption, output scrap and quality. You will be able to record non-productive and rework time for advanced reporting to help reduce inefficiencies You will also record time and attendance based on employee shifts and automatically calculate overtime and shift differentials for integration with payroll systems.

This Shop Floor Module for Microsoft Dynamics 365 Business Central is packed with many great features. Whether you are a small Job Shop or a large manufacturer, this solution is an affordable capability for any size business

-

Eliminate manual time entry with barcode scanning for Production Orders, Jobs, Service Orders, and Fixed Assets

-

Capture operational data on the shop floor including consumption, output, scrap, and quality

-

Record and report on non-productive and rework time for better insight into lost productivity

-

Record time and attendance based on employee shifts with exception reporting

-

Easily approve time with exception-based supervisor approvals

-

Automatically calculate overtime and shift differentials for integration with payroll systems

Professional Production Management

Shop Floor Insight utilises barcodes or touch screens to simplify data capture on the shop floor and reduce the errors associated with manual time entry.

Streamline Shop Floor Data Capture

Enhance data capture and management using Shop Floor Insight’s intuitive user interface. Employees can quickly record time against production orders, non-productive activities, and maintenance using shared or individual shop terminals or devices.

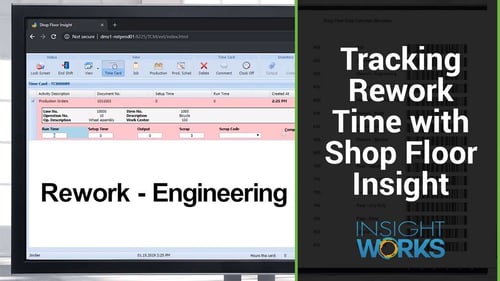

Significantly reduce Manufacturing Rework

Rework is a major issue for many manufacturers. Identifying and capturing rework time can often be extremely tedious and difficult with manual systems. Shop Floor Insight makes it simple to capture rework on the shop floor and to analyze the root causes to help reduce costs and improve productivity.

Real-time reporting

Real-time reporting enables users to analyze job progression and costing; providing immediate feedback to supervisors and planners while maintaining a detailed production history. Shop Floor Insight data is easily accessible through Power BI and other tools for detailed reporting.

Reduce Labour costs and data entry errors

Automate the time collection process to significantly reduce the labor costs and data entry errors associated with manual entry. Users enter time and attendance information directly into Microsoft Dynamics 365 Business Central, with simple supervisor approvals.

Built-in validation and configurable payroll rules eliminate manual payroll data management. Shop Floor Insight’s intuitive shop floor interface reduces training time and minimizes change for the end users, helping to ensure a successful and cost effective rollout.

Customisable and configurable

Customisable rules further reduce the time and effort required to calculate overtime and other variables. Configurable work types, payroll codes, project types, and shift patterns adapt to all potential workforce configurations.

Clear communication

In the event of time card issues, collaboration tools allow the payroll department to efficiently communicate directly to responsible personnel. Resolving time card issues at the source helps to minimize the time required for resolving discrepancies after payroll has been run.

An investment in your company

Shop Floor Insight pays for itself in as little as three months. By automating your shop floor data collection, you will increase data accuracy, reduce unnecessary overhead costs and improve the efficiency of your staff; helping to enable your staff to focus on value added tasks to drive business performance.

The Shop Floor insight ROI calculator will help you to estimate some key financial benefits of the solution:

-

How much overhead time can be saved by automating your shop floor data collection.

-

Savings gained from increased quality.

-

The increase in sales driven by improved efficiency and quality.

-

The payback period for Shop Floor Insight.

Features

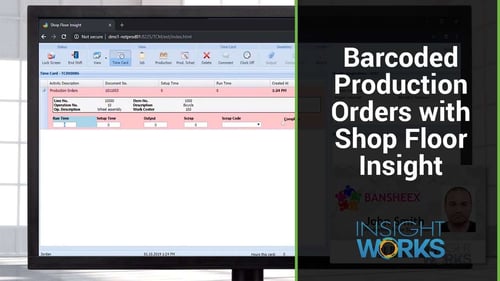

Barcoded Production Orders and Jobs

Speed shop floor time collection while simultaneously reducing data entry errors

Shop Floor Insight utilizes barcodes on the shop floor to streamline system access and simplify the process of collecting time against operations on a production order.

Users will scan an ID badge equipped with a barcode that will log them into the system and depending on the configuration will display the open timecard or a dispatch list of production orders. Once logged in users simply scan the barcode on the production order to start working. Shop floor users can also capture nonproductive time such as machine downtime on the shop floor by scanning the appropriate barcode.

The use of barcoding simplifies the shop floor data collection process, ensuring the quality of the data while minimizing the overhead for the shop floor staff.

Shop Floor Data Capture

Quickly and easily execute day-to-day tasks with ease

Shop Floor Insight provides tools that can easily import information from external document management systems if required, as well as extends capabilities that document valuable data for informed decision making. The full MES option enables users to view linked documents, record production consumption and output, enter quality measures, view and enter production comments and manage dispatch lists for job and production orders.

Scan or type to record information instead of losing mission-critical information written on paper, such as work instructions and record links, stock numbers at the point of use, lot and serial numbers that are going to be produced, how much has been completed at particular stages of production, how much has been scrapped, and what the scrap code is; which can be recorded right on the line if enabled.

Users can create inspections against incoming receipts and outgoing shipments where fields and acceptable values can be defined. By determining your logic on how to respond if there is a failed test, users can assign test definitions with anything in the system. This will prompt the system to alert users if they try to start the next operation on a production order with a failed test.

Capture Rework Time

Improve visibility into neglected cost areas by collecting and analyzing rework time

Studies show that “finished” products don’t pass inspection 20% of the time and that rework is required. The cost of rework can be a considerable expense for a company and so there is an opportunity to improve profit margins if rework can be reduced.

The key to reducing rework is data. More specifically, what is the cause of the rework and exactly how much is the rework costing a company.

Shop Floor Insight enables users to find the root cause to any rework required as well, Shop Floor Insight tracks the hours dedicated to just rework.

Using built-in reports, companies can easily identify why rework is needed and create processes to reduce rework.

Simplified time validation & approval

Easily locate anomalies to reduce validation time and costs

Shop Floor Insight’s simple and efficient tools enable management to review open time cards for any potential issues prior to approval.

Shop Floor Insight will alert supervisors with visual cues if there are validation issues during the approval process, making the work of approving time cards quick and easy. Supervisors can use the approval interface to review all employee time details, adjust clock in/out times, adjust recorded time on activities, and send notes to payroll or other users.

Payroll Integration

Ensure accurate payroll processing by eliminating double entry

The time & attendance data collected by Shop Floor Insight can be easily exported for integration with any payroll provider. Payroll users can easily export the data to excel or a custom export can be developed for integration with specific payroll providers. Electronically transferring the payroll data helps to ensure the data is entered accurately into the Payroll system and reduces the overhead of double entry.

Adapt to all potential workforce configurations by enabling user capabilities with configurable payroll rules

Payroll rules in Shop Floor Insight are configured based on daily or weekly shift patterns. The module also includes the ability to configure rules for overtime and copies fully summarized data to the time journal to ensure there is no need to calculate overtime. Overall, Shop Floor Insight’s configurable payroll rules provide valuable data on how much labor companies are spending, how much downtime companies have, and why they are down.

Meet virtually any business requirement for payroll codes, project types and shift patterns

Shop Floor Insight offers configuration options to meet virtually any business requirement for payroll codes, project types and shift patterns. Pre-configured attributes are available and users have the ability to add additional ones as required.

Leveraging this flexibility, Shop Floor Insight can be tailored to companies with configuring project types, payroll codes and patterns, helping help companies meet the unique requirements of their business, as well as providing accurate and organized data.

Shop Floor Insight alerts users if there are validation issues such as “setup time was not entered” or “total hours on time card is less than expected,” highlighting all issues in red for easy visibility. Users have the ability to look at routing for the production orders, and see how much time has been put against the production order in the shop that has not yet been approved. This provides rounding rules that can be applied to shift patterns, as well as a record of historical data, warranty or quality issues, and even shows when the work was done and who it was done by.

Mitigate risks and enhance accountability with multi-level approvals of time

Shop Floor Insight enables management to review time collection data using a strong system of checks and balances. Using an easy-to-use interface, users can indicate reporting structures with the ability to configure as many reporting levels as required.

Using this feature, managers will only see time cards for staff that they manage and can approve time using a simple approval process. The approval process assists managers by highlighting data that needs to be reviewed prior to approval. When reporting structures change it is quick and easy to modify them within Shop Floor Insight.

Time Collection Module enables management to review time collection data using a strong system of checks and balances. Using an easy-to-use interface, users can indicates who reports to who with the ability to customize as many reporting levels as required.

Using this feature, employees can filter time cards by who they manage using an easy approval process. The approval process assists employees by marking data that needs to be reviewed in red, showing issues per line. For example: If the project budget indicated that 100 hours would be worked in 8 hour increments per employee and there is a time entry for 5 hours, appropriate personnel have the ability to review data to determine why. Time Collection Module also ensures that changing personnel responsible for time collection of specific employees is quick and easy in the event that job roles change.

Facial Recognition

Increase accuracy and security with facial recognition system login

Both users and administrators will appreciate the hands-free facial recognition feature built into Shop Floor Insight. Simply walk up to the workstation, look into the camera and you’re instantly logged in and presented with your assigned production orders.

Increased security

With facial recognition, misplaced or stolen ID badges can no longer be used to log into Shop Floor Insight. As well, people can’t be logging in on behalf of someone else. In the event you do allow ID badge scans, Shop Floor Insight will snap and store a photo of the person accessing the workstation.

Fast and accurate

With facial recognition, you get a verification method that is convenient, quick and accurate.

No contact

Fingerprint authentication doesn’t work well in a manufacturing environment where there is dirt, grime, and gloves. Facial recognition is a clean, reliable, and no-contact authentication method.

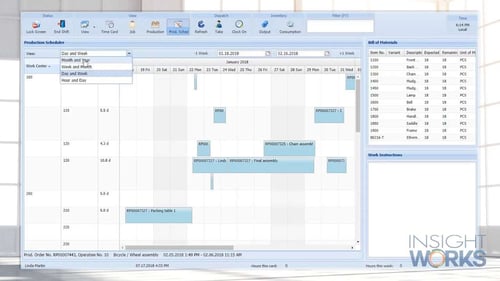

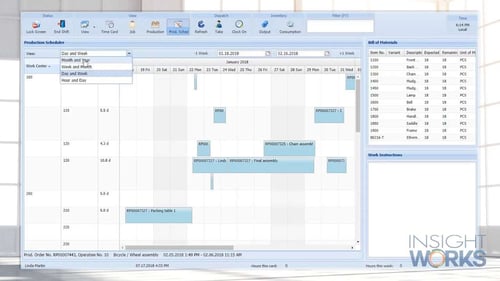

Scheduling & Graphical Dispatch List

Manage loading more effectively with a visual production scheduler

Shop Floor Insight adds a graphical layer to Dynamics 365 Business Central production schedule enabling production managers and employees to view and manage loading more effectively.

With Shop Floor Insight, you’ll easily visualize exactly what work is scheduled at each workstation. The graphical interface enables employees to clock on, record output and perform all tasks you can normally do with the dispatch list.

The visual production schedule is more than a display. Users, with the appropriate permissions, can drag-and-drop an operation on a production order to a new work center and time. As work is rearranged, associated operations will automatically update to reflect a new production schedule.

Clicking on a specific production order operation will also display additional details.

Tracking Quality

Easily manage your quality assurance process to increase customer satisfaction

Customer satisfaction includes delivering products and services free of defects and shortcomings. Shop Floor Insight helps ensure you deliver what your customer expects by including a fully configurable quality module.

Shop Floor Insight helps reduce rework and returns by enabling you to track information that pertains to quality. Whether you need to collect information for audits, comply with 3rd party regulations, track batch information, check that shipments are prepared correctly or ensure parts are produced within spec, Shop Floor Insight makes it easy.

With Shop Floor Insight, you’re in control. When it comes to monitoring quality, the task can be assigned to an employee, asset or process. In addition to the quality information you choose to collect, pass/fail parameters can be configured to confirm acceptance or indicate a problem that needs to be resolved.

Real-Time Reporting

Accurately evaluate job progression and costing in real-time

Managers can monitor job and production order progression and costs in real-time at every stage of the manufacturing process. Shop Floor Insight reporting enables managers to review which employees completed specific tasks. Managers can now see how much time each person has put towards operational productivity helping to identify bottlenecks and employee utilization issues. By utilizing Shop Floor Insight reporting tools, managers can make better-informed decisions related to staff utilization and scheduling.

Consistent User Interface

Make tracking non-shop time and attendance simple

Shop Floor Insight supports time and attendance tracking for non-shop floor staff providing a consistent look and feel that Dynamics 365 Business Central users will be comfortable with. Standard BC functionality is available to users such as filtering, drop downs, lookups, data exports etc. Non-production time is logged in the same table as shop floor time providing a holistic view of labor costs for the organization.

Intuitive Shop Floor User Interface

Speed up adoption with an intuitive interface that looks and feels like a paper time card employees are used to

The shop floor user interface has been designed to be simple and intuitive, presenting the data in a format that users on the shop floor are used to and comfortable with.

Shop floor users record labor usage, output, scrap and completion against operations on a production orders or multiple production orders. Production orders can be selected from a dispatch list or by scanning a production order traveler report equipped with barcodes. Capturing labor time is very simple and depending on configuration can be manually entered or calculated based on scan times.

Supervisor capabilities are extended with the ability to manage set up time, capture set up time independent of run time, and deduct break times manually or by scanning a barcode.

Security of the shop floor interface has been designed to be simple but effective. Users scan their badge to log in, start working on a production order and log out. There is also a configurable timeout that can be setup which ensures that data is accurately captured for each user.

Improve shop floor efficiency with user profiles

Shop Floor Insight enables users to create user interface profiles for users, groups and even globally. A configurable user interface means Shop Floor Insight can easily be tailored specifically to your production environment to improve shop floor efficiency.

Streamline your process using color

By assigning colors to various components, users will easily configure Shop Floor Insight to provide better visibility when viewing time cards. For example, Shop Floor Insight can highlight time card tasks that are still open making it easy for production workers to identify tasks, or identify if an employee is clocking setup or run time.

Safety Logbook

Enhance the quality and effectiveness of your safety program

Your safety program is a critical part of your business, and proper record keeping is crucial to keeping it compliant with regulatory agencies and industry groups. The Safety Logbook feature of Shop Floor Insight makes it simple. With Shop Floor Insight, you will improve shop safety by recording and publishing hazard assessments, logging and implementing corrective actions, and tracking employee certifications and training.

Ensure your safety records are always thorough and up-to-date. The Safety Logbook provides integrated record keeping for certifications, near misses, incidents, and all other HSE-related activities. Generate employee history reports, management dashboards, and comprehensive incident investigation reports.

With the Safety Logbook, you’ll promote safety best practices and improve the quality and effectiveness of your safety program.

- Enhance the quality and effectiveness of your safety program

- Improve shop safety by tracking corrective actions and hazard assessments

- Manage compliance with governmental regulations

- Track and analyze all safety-related incidents and activities

- Generate or print an employee’s entire HSE history, including certifications and incidents

- Properly plan for employee re-certification